In the realm of lighting engineering, customization offers a tailored approach to meeting specific lighting needs and achieving desired outcomes in various applications. However, before embarking on the customization journey, it's essential to have a comprehensive understanding of several key factors that influence the design, functionality, and performance of engineering lights. Let's explore these considerations to ensure a successful customization process.

Understanding Lighting Requirements:

Before diving into customization, it's crucial to understand the specific lighting requirements of the intended application or space. Consider factors such as the purpose of the lighting (e.g., task lighting, ambient lighting, accent lighting), lighting levels needed for adequate illumination, desired color temperature, and any architectural or design considerations that may impact lighting placement and aesthetics.

Assessment of Environmental Conditions:

Environmental factors play a significant role in determining the suitability of engineering lights for a particular application. Assess factors such as ambient temperature, humidity levels, exposure to dust or moisture, and the presence of hazardous substances. Understanding these conditions will help in selecting materials, components, and protective measures to ensure the durability and reliability of customized lighting solutions.

Evaluation of Regulatory Requirements:

Compliance with regulatory standards and industry specifications is essential to ensure the safety, performance, and legality of engineering lights. Familiarize yourself with relevant regulations, codes, and standards governing lighting design, electrical safety, energy efficiency, and environmental impact. Compliance with standards such as UL, DLC, CE, RoHS, and ENERGY STAR may be necessary depending on the intended market and application.

Consideration of Energy Efficiency Goals:

Energy efficiency is a key consideration in modern lighting design, driven by the growing emphasis on sustainability and energy conservation. Before customizing engineering lights, establish energy efficiency goals and explore strategies to minimize energy consumption while maximizing lighting performance. This may involve selecting energy-efficient light sources, optimizing lighting control systems, and incorporating smart technologies for energy management.

Budgetary Constraints and Cost Analysis:

Customizing engineering lights involves financial considerations, including upfront costs, ongoing maintenance expenses, and total cost of ownership. Conduct a comprehensive cost-benefit analysis to evaluate the economic viability of customization options. Factor in expenses related to design, prototyping, testing, production, installation, and long-term maintenance to ensure that customized lighting solutions align with budgetary constraints and provide value over their lifecycle.

Engagement with Stakeholders and End Users:

Collaboration with stakeholders and end users is essential to ensure that customized engineering lights meet their needs, preferences, and expectations. Engage in dialogue with architects, designers, engineers, facility managers, and occupants to gather insights, gather feedback, and incorporate user-centric design principles into the customization process. Addressing end user requirements and preferences will enhance user satisfaction and acceptance of the customized lighting solution.

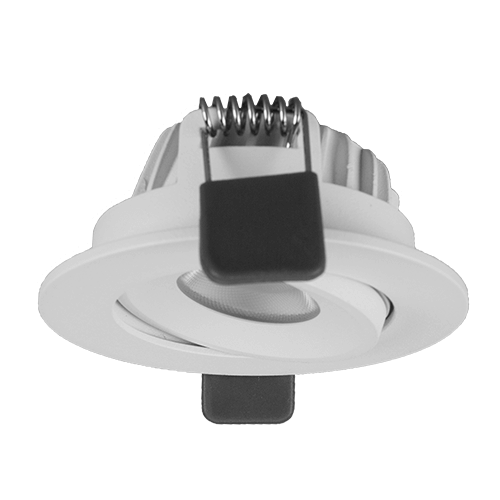

Selection of Suitable Components and Technologies:

Customizing engineering lights involves selecting appropriate components, technologies, and manufacturing processes to achieve the desired functionality and performance. Evaluate available options for light sources (e.g., LED, fluorescent, HID), optics, drivers, controls, thermal management systems, and enclosures. Choose components and technologies that offer reliability, efficiency, longevity, and compatibility with customization requirements.

Risk Assessment and Mitigation Strategies:

Identify potential risks and challenges associated with customizing engineering lights and develop mitigation strategies to address them effectively. Anticipate risks related to design complexity, technical feasibility, supply chain disruptions, regulatory compliance, and performance uncertainties. Implement measures such as prototype testing, quality assurance protocols, and contingency plans to minimize risks and ensure project success.

In conclusion, before customizing engineering lights, it's essential to understand and address various considerations related to lighting requirements, environmental conditions, regulatory compliance, energy efficiency, budgetary constraints, stakeholder engagement, component selection, and risk management. By carefully evaluating these factors and incorporating them into the customization process, you can develop tailored lighting solutions that deliver optimal performance, durability, and user satisfaction across diverse applications and environments.

Enhancing Outdoor Lighting with IP65 Rec

Enhancing Outdoor Lighting with IP65 Rec

Engineering Illuminated: Recessed Downli

Engineering Illuminated: Recessed Downli

How do recessed down lights improve ligh

How do recessed down lights improve ligh

Can recessed downlights enhance architec

Can recessed downlights enhance architec